Legends Equipment Blog Series “Setting Industry Standards for the Industrial Central Vacuum Systems.”

Selecting the right style of exhauster for a central vacuum system.

An industrial central vacuum system is different from other manufacturing processes. We encounter a lot of central vacuum systems that are not operating as well as they should. Legends Equipment is working on a series of blog posts to address common problems we encounter and how to avoid these when designing a new central vacuum. This document covers blower selection and explains why a multi-stage centrifugal exhauster is ideal and why other blowers can only be used in specific instances.

Central vacuum systems are not dust collection systems. A dust collector uses high volumes of air to move dust already airborne into the ductwork and out to a dust collector. These are high CFM and relatively low static pressure (typically 10” to 20” H2O). A central vacuum uses high static pressure at low CFM intended to get dust and product that is at rest lifted from a floor or surface. A central vacuum can commonly require vacuum levels from 100” to 150” H2O. This is why connecting a 1-1/2” or 2” vacuum hose to a dust collector does not effectively clean floors and equipment, they lack the “suction” needed to get dust at rest, off floors, and equipment.

Central vacuum systems are not pneumatic conveying systems. A pneumatic conveying system can operate at a similar vacuum level to a central vacuum. However, the difference here is that most systems are set up as a fixed systems with inlets and receiver points that do not change. Most pneumatic conveying systems are a set pipe diameter from pick up to the receiver with a constant CFM engineered specifically to that material. These are constant airflow with a variable vacuum/pressure.

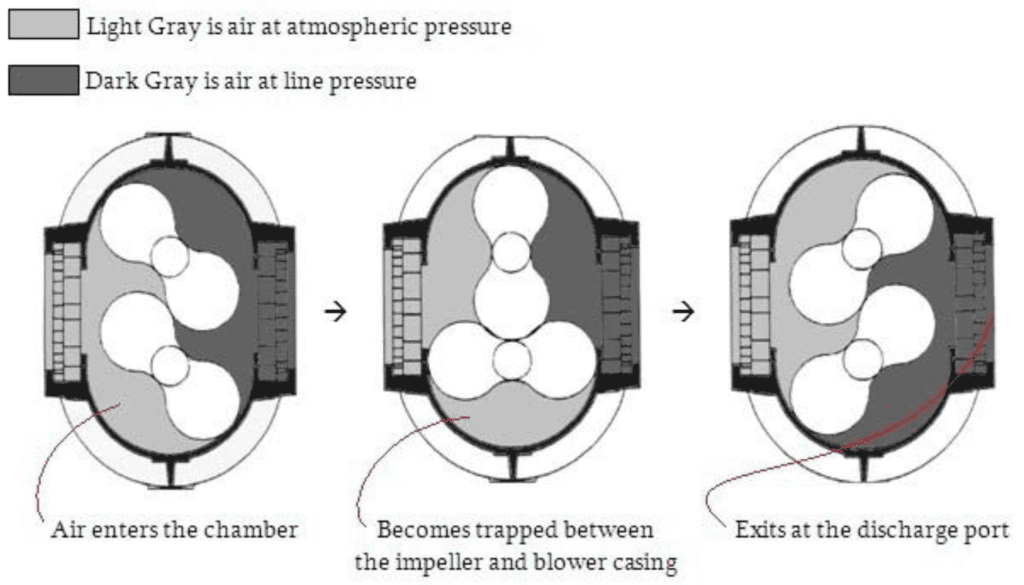

A positive displacement blower (PD Blower) is perfect for a pneumatic conveying system because it positively displaces the same volume with every turn giving contact CFM. And if the line pressure builds up, the PD will react by generating more pressure to overcome line plugs.

While this is the correct blower for pneumatic conveying, it cannot react to the changes of a multiple-user central vacuum system. A central vacuum system that handles multiple operators needs a constant vacuum level over a wide range of airflows. When only a single operator is using the system, the CFM is at its lowest level. And the pump needs to add more CFM as additional operators connect hoses and use the system for cleaning. For a PD to change CFM, you need to change the RPM of the unit. This could be done with a VFD, but how do we know when more operators are using the system? This would require a full control system run through the facility and an elaborate program to speed and slow a PD as more operators use the system.

A multi-Stage centrifugal exhauster is ideal for these applications. This type of exhaust has a steady vacuum at variable volumes. As the demand for more air changes, the multistage centrifugal will pull more CFM and increase horsepower. No VFD for valves is needed; the blower simply reacts and accounts for the added demand. This is why the manufacturers of multistage exhausters were the original central vacuum suppliers. The application fits perfectly into their design.

A multi-Stage centrifugal exhauster is ideal for these applications. This type of exhaust has a steady vacuum at variable volumes. As the demand for more air changes, the multistage centrifugal will pull more CFM and increase horsepower. No VFD for valves is needed; the blower simply reacts and accounts for the added demand. This is why the manufacturers of multistage exhausters were the original central vacuum suppliers. The application fits perfectly into their design.

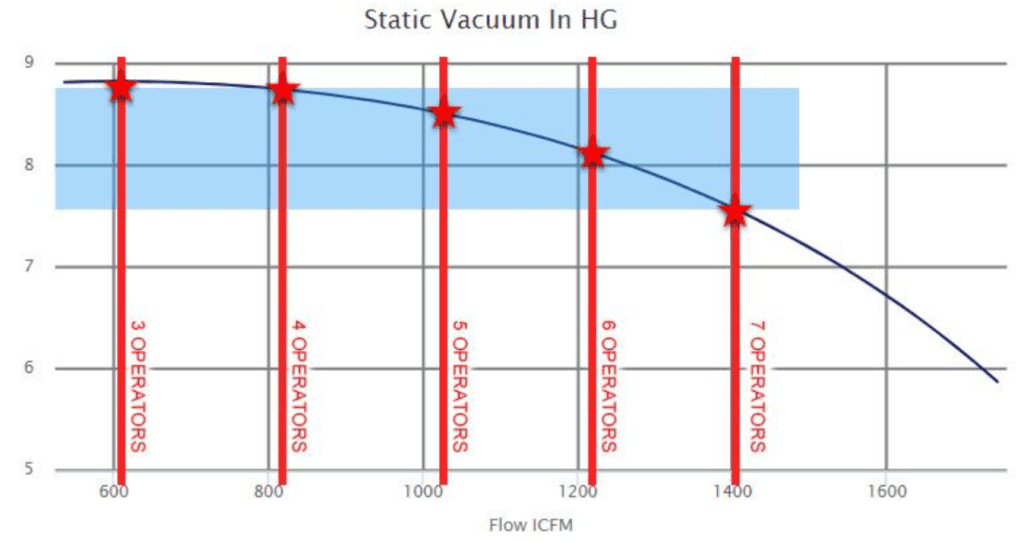

For example, here is a curve showing the CFM and Vacuum. As the CFM increases (More operators), the vacuum holds within 1.5” HG over a range of 500 to 1500 CFM.

When you compare this to a PD, while the unit can handle the upper end of the requirements, with a fixed RPM as CFM reduces the unit quickly hits maximum vacuum and will release the vacuum breaker.

Power Consumption

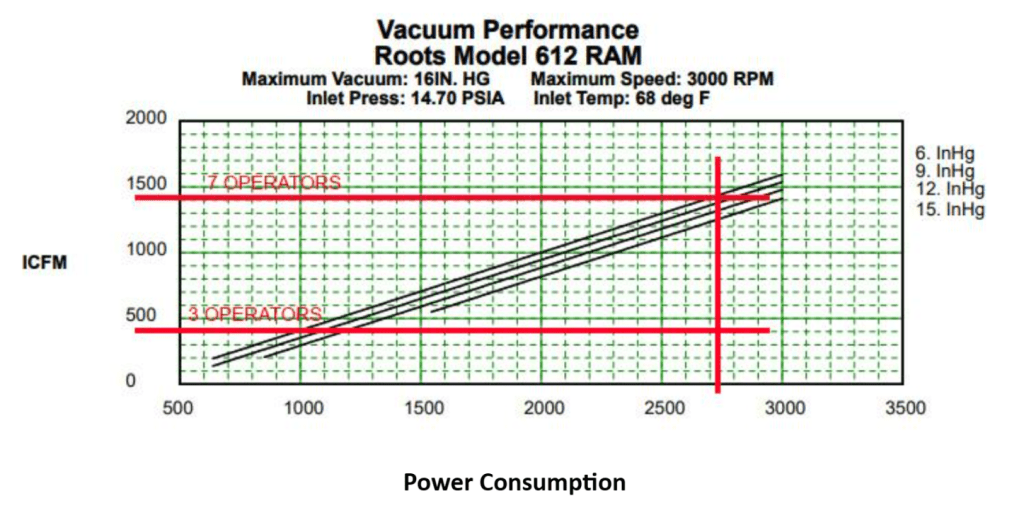

Many central vacuums are used with one, two or three users during normal operating times. Then at the end of a shift, you will see the maximum number of operators. In this example, we are looking at seven simultaneous operators. However, we should assume only a couple of operators will be using the system.

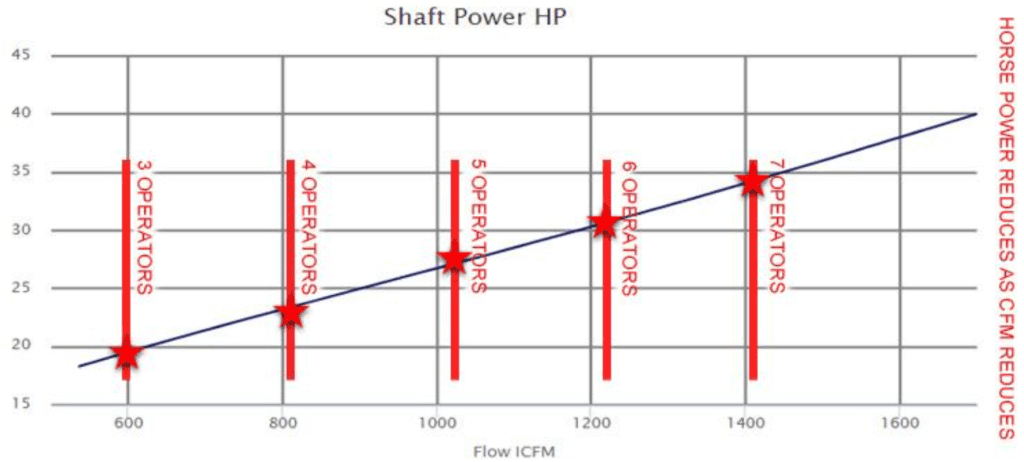

When no one uses the system, a vacuum relief valve will allow the unit to operate at 18 Horsepower. As operators plug in hoses, the horsepower increases. You are only paying for the power of the work being done.

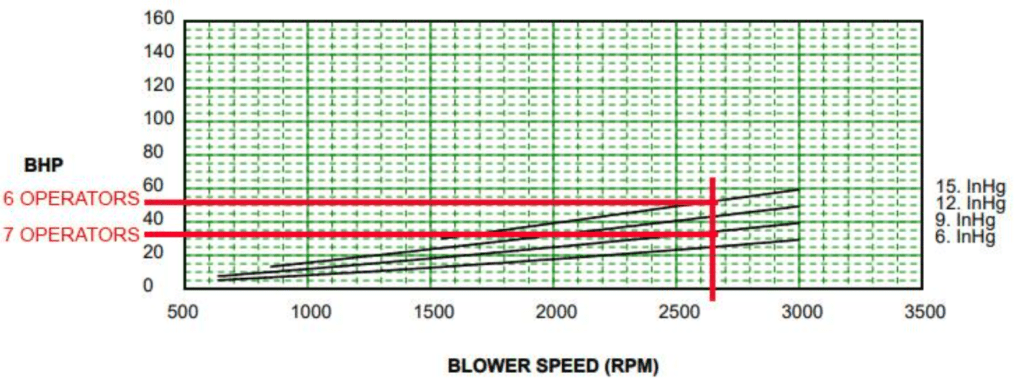

The PD blower reacts differently. The RPM is fixed. As CFM drops, the Horsepower quickly ramps up.

You can see on this curve as the CFM drops from 7 users down to 6 users, the horse power goes from 30HP to 50HP. Any conditions less than 6 users will remain at the maximum vacuum and maximum horsepower. At all conditions except for maximum users, this unit will run at full horsepower.

Filter Life

The PD blower is a fixed RPM and, therefore, a fixed CFM. In our example here, we have sized for 1,400 CFM to account for the maximum number of users. The PD will always be running at 1,400 CFM. The filters are always going to always see this CFM. While this is acceptable, you do not get the advantage of a centrifugal.

The centrifugal’ s ability to adjust CFM, has the added advantage of extending filter life. The filters are sized to handle the 1,400 CFM, but as fewer users are using the system, the CFM reduces, resulting in a lower air to cloth. A 1,400 CFM filter running at lower CFM will give better filter life and better cleaning release.

Summary

The multistage centrifugal has other advantages. They are large cast iron machines resulting in lower sound levels. They are also direct drive without a gearbox resulting in less maintenance.

A PD can be used on some systems. If you are looking for a good 1 or 2-user system, these machines can handle some changes in CFM. A PD can also be used on extremely long runs because they do typically generate more vacuum, but the fixed CFM still limits the range of operators.

Regenerative exhauster works well for smaller systems. They are also a good solution when looking at one, two, and some three-user systems.

A high static fan can be used for some materials that need higher CFM volumes at lower static pressures. These are the street sweepers that collect leaves, sawdust or wood shavings.

But the common mistake we see in the field are large central vacuum using a PD as the vacuum source. They can be made to function, but cost more to operate, and require complicated valves and controls. The Centrifugal exhauster handles everything by design, making it the perfect fit. The larger the system range the more glaring these differences are.

If you have any questions and want to discuss the various solutions, Legends Equipment is available to review, discuss and compare blower selections. Every system is different, and we are here to help get your system running at its best.